About Energy storage pulse arc welding

The modification of welding current waveform according to practical conditions and requirements, is an important way to improve the welding quality of various metals, especially the application of high-frequency pul.

With the development of social production, higher requirements are put forward for welding.

2.1. High-frequency pulsed current waveformIn the fusion welding process, the introduction of ultrasound can improve the crystallization co.

3.1. Arc characteristics and metal droplet transferAs a source of heat and force in the welding process, welding arc is critical to metal droplet transfer.

It has already been known that the traditional pulsed GTAW welding has the disadvantages of higher heat input and distributed arc energy, while increasing the pulse frequency.

It is still at an early stage in the study of high-frequency pulsed arc welding, which needs to be improved. On the one hand, the effect of high-frequency pulsed arc on the formation an.

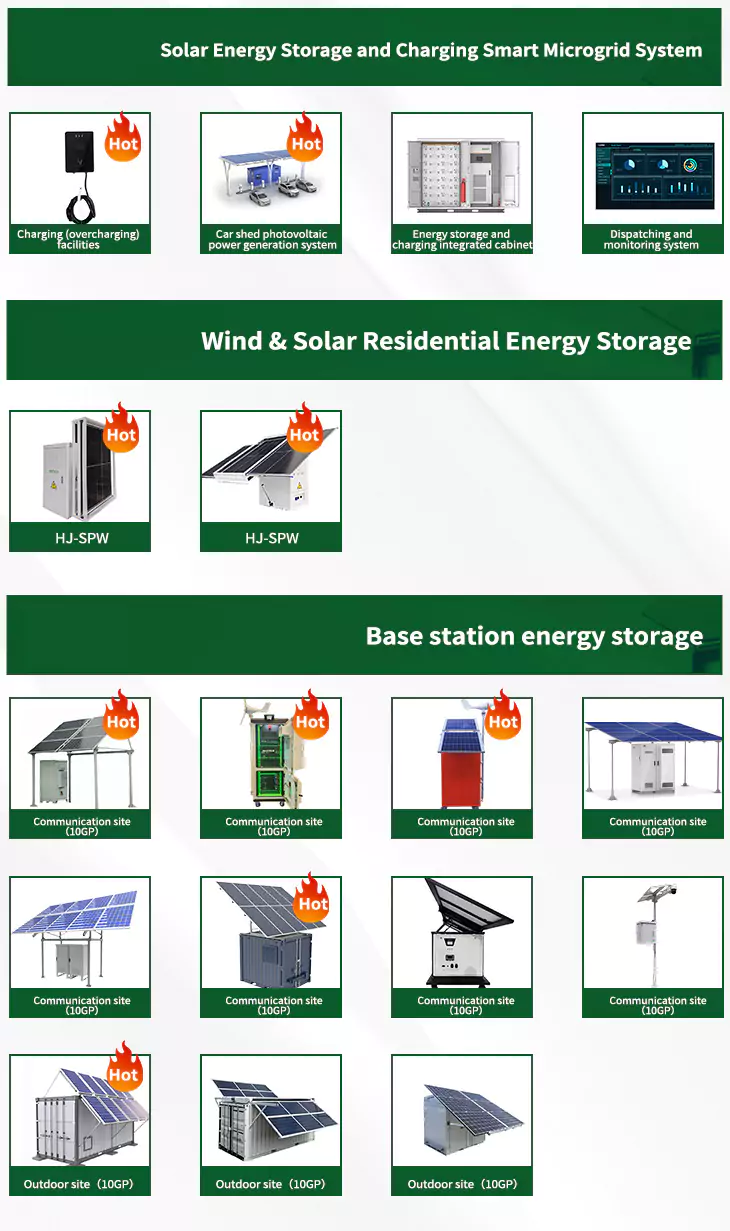

As the photovoltaic (PV) industry continues to evolve, advancements in Energy storage pulse arc welding have become critical to optimizing the utilization of renewable energy sources. From innovative battery technologies to intelligent energy management systems, these solutions are transforming the way we store and distribute solar-generated electricity.

When you're looking for the latest and most efficient Energy storage pulse arc welding for your PV project, our website offers a comprehensive selection of cutting-edge products designed to meet your specific requirements. Whether you're a renewable energy developer, utility company, or commercial enterprise looking to reduce your carbon footprint, we have the solutions to help you harness the full potential of solar energy.

By interacting with our online customer service, you'll gain a deep understanding of the various Energy storage pulse arc welding featured in our extensive catalog, such as high-efficiency storage batteries and intelligent energy management systems, and how they work together to provide a stable and reliable power supply for your PV projects.

Related Contents

- Energy storage welding machine arc breaking

- Energy storage pulse welding machine

- Capacitor energy storage arc welding machine

- Argon arc welding energy storage inductor

- Capacitor energy storage welding control

- Kosovo energy storage welding machine supplier

- Energy storage welding bolt

- Energy storage welding standard parts

- Capacitor energy storage seam welding skills

- Pulse power energy storage liquid

- Energy storage spot welding machine ranking

- Berlin energy storage welding machine price